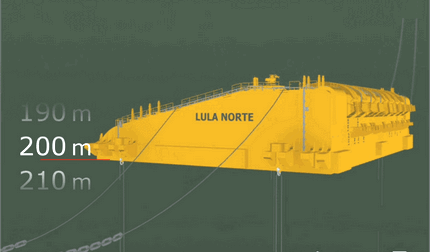

MADURA Floating Production Unit

This is the 1st new built FPU EPC project that Jiangsu Strongwind, under Tri Ocean Management, has delivered for TOI, with its end user - HCML. The offshore Madura 3M Gas Fields Development Project urgently calls for the provision of an offshore spread moored floating production unit (FPU) as host facility connected via flexible jumpers to MDA, MBH and MDK sub-sea well head platform. The FPU’s designed processing capacity amounted to 17.5 billion cubic feet of natural gas per day.

Dimension-------------------------------160m*32m*11m

Design Draft-----------------------------4.4m

Displacement----------------------------18,874T

D/G--------------------------------------1200KW*1set

GTG--------------------------------------3000KW*2set

GTC--------------------------------------8282KW*2set

Main Crane-----------------------------17T * 1, 6T * 1

POB -------------------------------------70 People